توضیحات آگهی

- Condition:

- New

- Warranty:

- 2 Years

- After-sales Service Provided:

- Field installation, commissioning and training

- Place of Origin:

- China

- Brand Name:

- XINRONG

- Voltage:

- 380V

- Application:

- Pipe

- Weight:

- 30 tons

- Certification:

- CE

- Screw Design:

- Single-screw

- Plastic Processed:

- PE

- Dimension(L*W*H):

- 50000*3000*3000

- Applicable Industries:

- Manufacturing Plant

- Key Selling Points:

- High Productivity

- Output (kg/h):

- 180 - 1200 kg/h

- Screw diameter (mm):

- 120 mm

- After Warranty Service:

- Video technical support

- Local Service Location:

- Egypt

- Showroom Location:

- Egypt

- Material:

- Poly Ethylene

- Pipe size range:

- 1000-3000mm

- Operating direction:

- from right to left

- Center height:

- 3000 mm

- Machine color:

- Xinrong standard color (white)

- Cooling water consumption:

- 80 m3/h (≤20℃, ≥0.3MPa)

- Tank volume:

- 100 m3

- Compressed air consumption:

- 3 m3/min

- Power supply:

- 3 phase 400V

- Total power:

- 3950kW

- Selling Units:

- Single item

- Single package size:

- 500000X3000X3000 cm

- Single gross weight:

- 500.0 kg

- Package Type:

- China PVC Water Pipe Extrusion Manufacturing Machine Plant for Big diam can be designed according to customer's requirements. Large Diameter HDPE Structure Wall Pipe extrusion machine will be packged in the plastic film and loaded into the container.

- Lead Time :

-

Quantity(Set) 1 - 1 >1 Est. Time(days) 50 To be negotiated

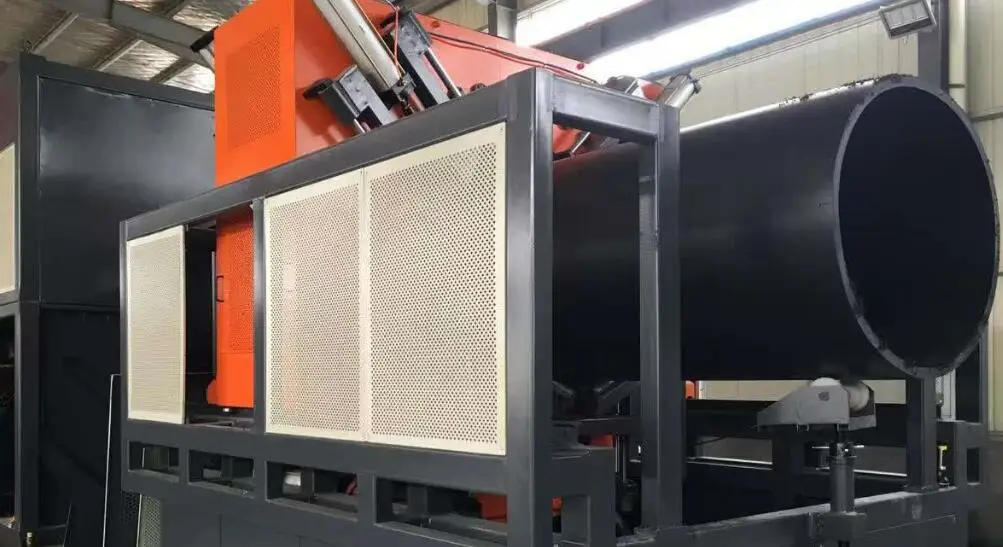

China PVC Water Pipe Extrusion Manufacturing Machine Plant for Big diameter pipe

SUMMARY

Material : PE (Poly Ethylene)

Pipe size range: Ø1000-3000mm

Operating direction: from right to left

Center height: 3000 mm

Machine color: Xinrong standard color (white)

Cooling water consumption: 80 m3/h (≤20℃, ≥0.3MPa)

Tank volume: 100 m3

Compressed air consumption: 3 m3/min (>0.5MPa)

Power supply: 3 phase 400V (±10%) 50Hz (can customize)

Total power: 3950kW

Actual power consumption: 2350kW

Overall dimension: 100000×8000×8000 mm

Control system:

Adopt German Siemens human-machine interface , liquid crystal displayer, new generation programmable micro-computer control system, all operating parameters can define and show on the scree, and can setup and revise rotation speed, traction speed, melting temperature and each zone temperature.

• DC speed regulator: Eurotherm , U.K

• Inverter: ABB or BOSH-REXROTH

• Low voltage electrical parts

Button, toggle switch Schneider, France

Contactor Schneider, France

Air switch Schneider, France

Intermediate relay Schneider, France

Temperature controller RKC, Japan

Heater magal alloy ceramic heater

Circumstance:

Working place: indoors

Power supply: no dangerous area

Temperature: 0-40℃

Single screw extrude, model SJ120×38 6 units

Auto dryer, loader 6 sets

Extrusion die head, model LXGM3000 1 unit

Die head support, model MXC3000 1 unit

Bush 8 pcs

Mandrel 16 pcs

Calibration sleeve 8 pcs

Mould temperature controller 8 units

Co-extruder for color line, model SJ45×30 1 unit

Vacuum tank, model ZDL3000Y 1 unit

Vacuum tank, model ZDY3000R 1 unit

Vacuum sealing device 1 set

Pipe clamping device, model GJC3000 1 set

Cooling tank, model PLX3000 6 units

Spraying sealing device 6 sets

Pipe support 8 units

Caterpillar haul off, model LDQY3000 1 unit

Features

The spiral structure of die head can ensure melt temperature uniformity, thoroughly eliminate confluence seam and reduce flaws such as bubble, black spot, unsmooth inside wall caused by too high temperature. With heat remove system which can exhaust heat inside inner wall of pipe and have better cooling effect.

Technical parameter

• Die material: 40Cr, forgings with tempering treatment

• Bolt grade: 12.9 grade high strength bolt

• Heating power: ≈500kW (zone control)

• Flow channel surface: chroming and mirror polishing, heating treatment hardness HRC52-56;

• Pipe range: Ø1000~Ø3000mm

Die head support, model MXC3000

Technical parameter

• Electric control

• Easy for mould assembling and disassembling

• Can replace bush and pin vertically

• With guide rail to move die head forward and backward

2.2 Bush

Features:

Processed by CNC , achieve precise dimension and realize stable extrusion.

Technical parameter

• Bush material 40Cr, forging with tempering treatment

• Pipe specification: Ø1000, 1200, 1400, 1600, 1800, 2000, 2500, 3000mm 8pcs

2.3 Mandrel

Features:

Processed by CNC, achieve precise dimension, realize stable extrusion.

Technical parameter

• Mandrel material: 40Cr, forgings with tempering treatment

• Pipe specification: Ø1000mm (SDR30), 1000mm (SDR21) Ø1200mm (SDR30), 1200mm (SDR21) Ø1400mm (SDR30), 1400mm (SDR21) Ø1600mm (SDR30), 1600mm (SDR21) Ø1800mm (SDR30), 1800mm (SDR21) Ø2000mm (SDR30), 2000mm (SDR21) Ø2500mm (SDR30), 2500mm (SDR21) Ø3000mm (SDR30), 3000mm (SDR21)

16pcs

Features:

Vacuum tank is used to shape and cool pipe, so as to reach standard pipe size. Its shape is advanced foreign anti-deformation structure. The cover is made of high quality casting aluminum alloy. The pipeline adopts the design of double loop pipeline, realizing non-stop pipeline clean and function of temperature control.

The biggest characteristic: supporter adopts nylon meniscus structure.

Technical parameter

• Center height: 3000 mm

• Tank material: stainless steel

• Tank length: 3000 mm

• Main material of pipeline: Stainless steel

• Vacuum degree: 0~0.08MPa (adjustable)

• Vacuum pump: 4×11 kW

• Water pump: 4×15 kW

• Moving motor power: 3 kW

• Adjust range of forward and backward: ±1000 mm

• Adjust range of up and down: ±80 mm

• Adjust range of left and right: ±60 mm

• With operating platform (with fence and feet protection plate)

4.1 Vacuum tank, model ZDY3000R

Features:

Vacuum tank is used to shape and cool pipe, so as to reach standard pipe size. Its shape is advanced foreign anti-deformation structure. The cover is made of high quality casting aluminum alloy. The pipeline adopts the design of double loop pipeline, realizing non-stop pipeline clean and function of temperature control.

The biggest characteristic: supporter adopts nylon meniscus structure.

Technical parameter

• Center height: 3000 mm

• Tank material: stainless steel

• Tank length: 10500 mm

• Main material of pipeline: Stainless steel

• Vacuum degree: 0~0.06MPa (adjustable)

• Vacuum pump: 8×11 kW

• Water pump: 8×15 kW

• Moving motor power: 4 kW

• Adjust range of forward and backward: ±1000 mm

• Adjust range of up and down: ±80 mm

• Adjust range of left and right: ±60 mm

• With operating platform (with fence and feet protection plate)

Features:

Its structure with sliding tempering glass door is beautiful and practical. Traction device with V type rubber block caterpillar and controlled by imported inverter can steadily haul pipe. It also features compact structure and free-maintenance.

10 caterpillars and 20 caterpillars can switch to meet the requirements to haul different size pipe. Adopt special automobile drive shaft to transmit power, stable and reliable. Length measuring device equipped with a rotary encoder, can ensure precise cutting.

Technical parameter

• Quantity of caterpillars: 20 pcs

• Effective length: 5500 mm

• Max. Hauling force: 200000 N.m

• Hauling speed: 0.02-2 m/min

• Clamping type: hydraulic press

• Hauling motor: 1.1kW × 20 (servo motor)

• Control method: servo control system

ویژگی ها

نشانی

سوژو, جیانگسو, چین